| ENGINE REASSEMBLY | 63 |

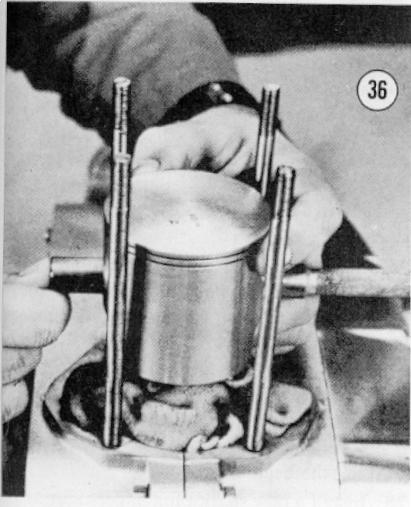

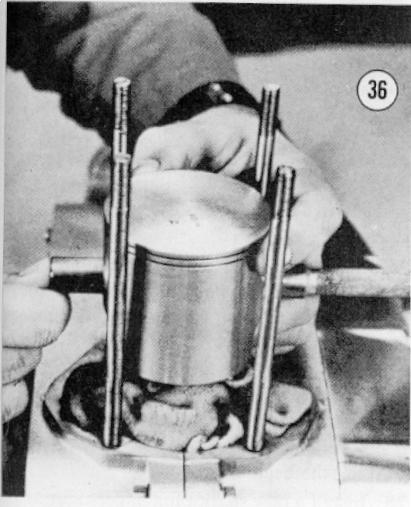

15. Align the piston and rod with tool number 999-202, sliding it through the bearing until it butts against the wrist pin.

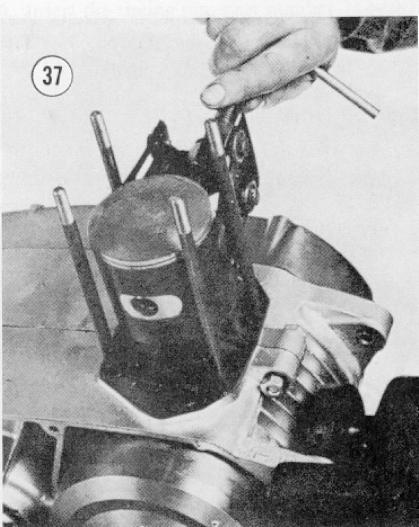

16. Push the wrist pin into place, forcing the special tool out (see Figure 36). If the installation cannot be made by hand, don't try to drive it with a hammer. Use a driving tool (see Figure 37) to install the pin.

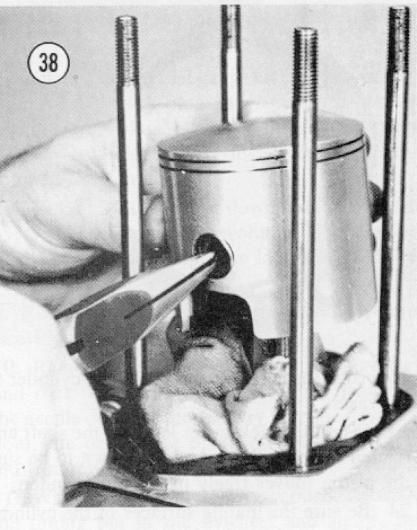

17. Install the circlips on both ends of the wrist pin (see Figure 38). Use new circlips with each installation.

18. Coat the piston rings with oil and install the rings with the peg in the ring groove centered between the ends of the ring.

19. Remove the rag from the crankcase and turn the engine until the piston is at bottom dead center.

20. Install the cylinder on the studs until the bottom rests against the top piston ring.

21. The bottom inside of the cylinder liner has a chamfered edge to make fitting it over the rings easier. Compress the rings with your fingers and slide the cylinder down over it (see Figure 39) to the cases.

22. If you prefer, you can make a ring compressor from a hose clamp (see Figure 40). Bend out the top edge of the clamp and then install it around the rings (see Figure 41). Leave it loose enough so it will slide down as the cylinder is lowered. Then remove the clamp when the rings are inside the cylinder,and lower the cylinder to the cases.