NOTE: If you lack the proper measuring equipment or the skill to use it, take the cylinder and piston to a dealer to have them measured. The piston-to-cylinder clearance is critical for good engine operation.

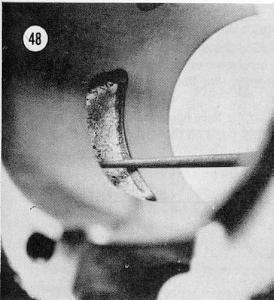

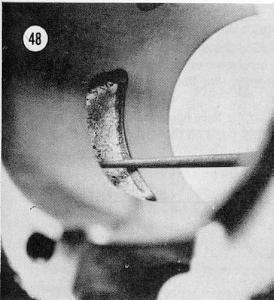

8. After boring and honing the cylinder, bevel the ports with a

.020" radius. Use a small grinder or a small file (see Figure 48).

Be sure all edges are beveled, or the rings can catch in the ports and

break.

9. With your old piston, check the rings for freeness in the lands.

If they are free, remove them one at a time and label them top and bottom

and mark which edge was facing up. They must go back on the piston

in the same position if they are used again.

10. Clean the rings and place them in the top of the cylinder one at

time (see Figure 49).

|

|

11. Push the ring down into the cylinder an inch with the piston (see Figure 50) to set it squarely in the bore.

12. Remove the piston and measure ring end gap (Figure 51). The gap should be 0,075" to 0,085".

13. Push the ring halfway down into the cylinder with the piston and measure the end gap again.

14. If either ring has too much end gap, replace them both as a set.