1. To repair the crankshaft requires special tools, including a press

with a minimum capacity of 15 tons, a fixture for pressing apart the flywheels,

an alignment jig for pressing them together again, and a set of machinist's

centers fitted with two dial indicators to check for alignment after crankshaft

reassembly. If you don't have these tools and the ability to use

them

properly, take your crankshaft to an Ossa dealer for repairs.

2. The crankshaft needs repairs when:

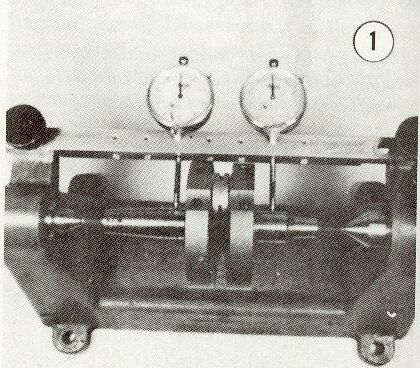

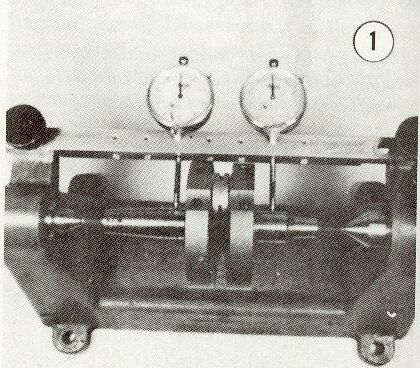

a. The connecting rod is damaged.3. Mount the crankshaft in a set of machinist's centers (see Figure 1). There should be no more than .001" runout of the flywheels, measured at the point where the main bearings mount on either side of the crankshaft.

b. The flywheels are not aligned within given tolerances.

c. Either flywheel is damaged.

d. The connecting rod, crank pin, and bearing are worn or damaged.

e. The connecting rod's small end hole is worn or damaged.

This is necessary because the rod is the outer bearing race and the

crank pin is the inner bearing race, and to replace one without replacing

both is a waste of time and money. The life expectancy of such a

bearing assembly would be extremely short.