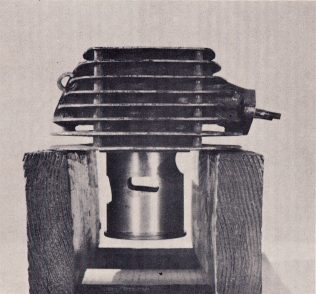

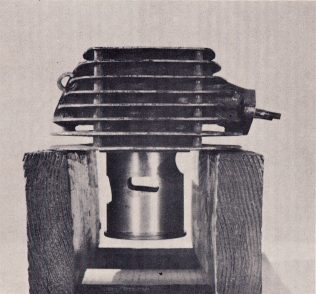

FIG. 72

Section: 7

1. If the cylinder walls become worn or damaged to such an extent that even boring to the 3rd oversize will not repair it, or if the 3rd oversize has already been fitted and now has excessive clearance, the cylinder liner will need to be replaced with a new one.Installing A New Cylinder Liner

2. To do this, place the cylinder in an oven and support it upside down by the fins, so that the liner will be free to drop out once it reaches the required temperature.

3. Set the oven to 5500 F. At approximately 5000 to 5500, the liner should drop out of the cylinder (Fig. 72). Occasionally the liner will hang up slightly inside the cylinder. This is due to the fact that at the factory, the ports in the liner are matched to the ports in the cylinder with an air grinder. This grinding sometimes results in a very small lip on the edge of the port between the cylinder and liner, and this lip catches the aluminum of the cylinder when the liner is being removed. When this happens the liner can be removed by gently tapping on its lower edge to assist it out of the cylinder.

FIG. 72

NOTE: Do not drive, force, or press the liner from the cylinder. This will result in damage to the cylinder which will impair its ability to transfer and dissipate the heat created during operation. DO NOT heat the cylinder to a temperature exceeding 750 deg. while attempting to remove the liner, or you face the danger of permanent cylinder distortion. If a liner proves to be particularly stubborn to remove, take it to a machine shop and have them turn down the inside of the liner on a lathe until it is thin enough to remove by gently breaking it apart.

4. After the liner is removed, allow the cylinder to cool and thoroughly clean the inside of it. Inspect for any gouges or scrapes that may have resulted when the liner was removed. If any such irregularities are present, carefully remove them with fine grit sandpaper, taking caution not to create a low spot in the cylinder by excessive sanding.

5. Place the cylinder back into the oven and heat it to 4000 to 4500 F. Remove it from the oven and support it right side up by the lower fins so that the liner can be dropped in from the top without hitting the bench.

6. Hold the liner just above the cylinder and turn it so that when it

falls into the cylinder, the ports will be fairly close to being aligned.

Page 54