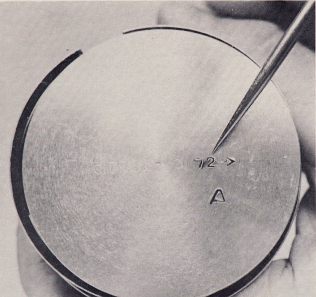

FIG. 64

FIG. 64

cylinder need not be bored if the piston is replaced with a new one of the same size.

5. If the tolerance would still be excessive with the new piston, then the cylinder will necessitate boring to the next oversize.

6. If the cylinder has worn excessively in one place, or been scratched deeply or gouged, the next oversize, being only .008" larger, may not be enough to remove the defects. In these cases it will be necessary to go to an even larger oversize, or perhaps replace the cylinder liner.

NOTE: The piston to cylinder wall clearance is a very important factor in determining the performance of an engine. Too little clearance can cause piston seizure. Too much can cause a considerable loss in engine performance and efficiency. The accuracy of measuring this clearance is dependent upon the type and quality of the measuring equipment and the amount of time spent in using them to obtain the most accurate readings, both before and after boring. For this reason, it is recommended that unless you have the proper equipment for this task, and the knowledge of how to use it, you take the piston and cylinder to a qualified motorcycle shop or machine shop to have it bored or measured.

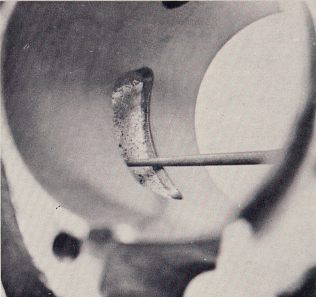

7. After boring and honing, the ports must all be bevelled, or rounded, where they enter the cylinder. Bevel all the port edges with a .020" radius. This can be done with a small air or electric grinder or a very small machinist's hooked file (Fig. 65). If a small grinder is used, be very careful not to let it slip and scratch the cylinder wall. This bevelling is very necessary, as it prevents the rings from catching in the ports as the piston passes them.

FIG. 65

Page 49