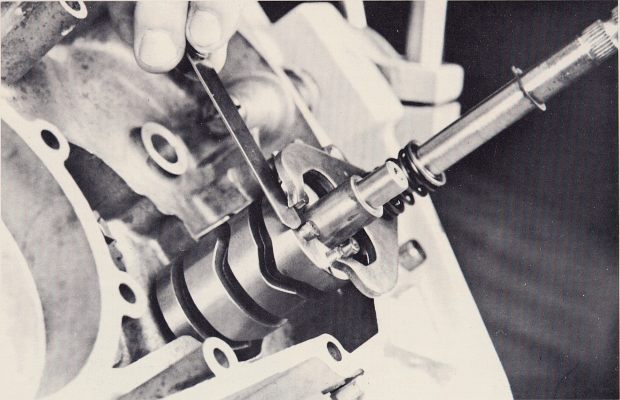

FIG. 61

Page 47

39. Finally, remove all the gearbox components, including the detent assembly, and reinstall only the shift drum and selector shaft assembly in the right case. Be sure that all of the shims on the shift drum are positioned properly. Insert a feeler gauge between the back of the selector pawl tips and the end of the shift drum (Fig. 61). This distance, although not critical, should be no less than .015- and no more than .080." If the measurement exceeds these limits, inspect the selector mechanism closely for damage and straightness, for under normal circumstances this cannot happen.

40. If the clearance is less than .015" and the selector assembly is not bent or damaged, the shaft can be shimmed away from the drum by installing shims on its right end. The shaft has a 14 mm diameter at that end. Therefore, the type shim used on the left end of the layshaft can be used for this purpose. If the clearance is more than .080" and no damage can be detected on the selector assembly, a new assembly should be installed and checked.

41. If you have a gearbox problem that you cannot cure by the use of this Manual, or if the necessary equipment is not available to you, give the engine to your OSSA dealer for repair. He will either repair it himself or send it to the OSSA distributor, as it may require the use of special tools and fixtures.

FIG. 61

Page 47