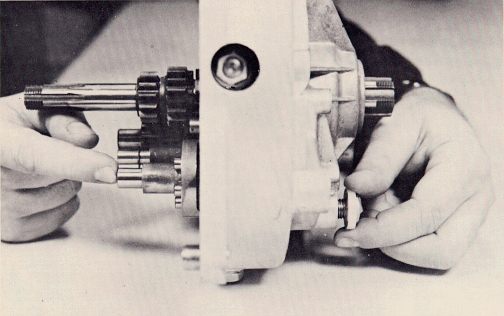

FIG. 59

Page 45

(d) LAYSHAFT SHIMMED TOO FAR IN ONE DIRECTION. This will give a condition similar to be a bent shift fork, whereas the 1st and 3rd sliding gear engages too far in one direction, but not sufficiently in the other. As long as at least one shim remains on the left end of the layshaft, all the other gearbox shims may be transferred from one end to the other to acquire the proper positioning of the shaft.

NOTE: The previously stated examples are extreme ones and, with the exception of a bent shift fork, will never be encountered under normal conditions. The vast majority of OSSA transmissions do not contain enough shims of sufficient thickness to drastically change the shifiting and engagement, regardless of where they are installed. This shimming information is given just in case this situation ever occurs, and also to give the ultra-conscientious mechanic the knowledge to align the shifting components perfectly.

32. Now that you have established the proper engagement of each gear and the shimming of the components, there are two final gearbox checks that should be made.

33. First, turn the shift drum counter clockwise to the 1st gear position. Then install the detent assembly into the right case. It is not necessary to screw it in all the way, but just two or three turns. While doing this, hold the shift drum to the right by putting your finger on the very end of it, as shown in Fig. 59. It is important that the shift drum is not moved to the left due to the force of the detent spring.

34. As you are screwing in the detent

FIG. 59

Page 45