10. Using a pair of external snap ring pliers, remove the snap rings

from both ends of the shifter fork shaft, and slide all three forks from

the shaft. Then take the first and third fork and insert it into the sliding

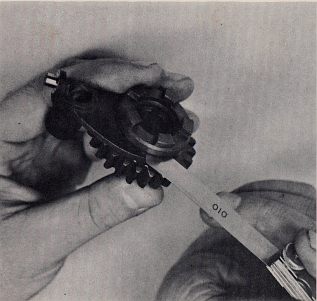

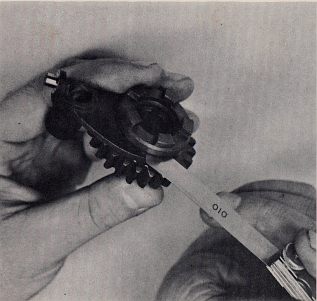

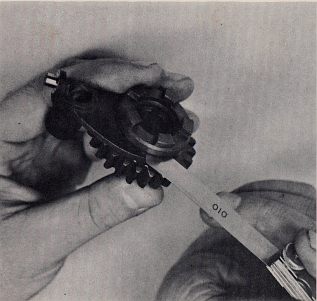

gear on the layshaft. Be careful not to install it upside down. Using a

blade type feeler gauge, measure the clearance between the thrust pads

on the fork and the inside of the groove in the gear (Fig. 42). Check both

pads on the fork and both sides of each pad. If you can insert a feeler,gauge

larger than .020" in any of these places, replace the shift fork. Repeat

this procedure with each fork by inserting it into its respective gear

or dog, and checking the clearance.

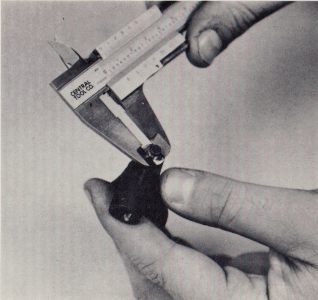

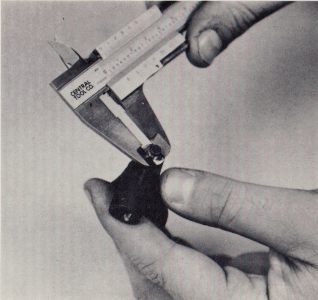

11. There is a peg on the rear of each shift fork that fits into one

of three machined grooves in the shifting drum. You must now measure the

diameter of each peg and measure the critical part of its corresponding

groove in the shift drum. This will tell you how much side movement the

shift forks will have when they are engaged in each particular gear. If

this side play is excessive, it could be the cause of a transmission jumping

out of gear, or missed shifts. First measure the diameter of the peg on

the first-third shift fork (Fig. 43.). Write

FIG. 42

FIG. 43

Page 30