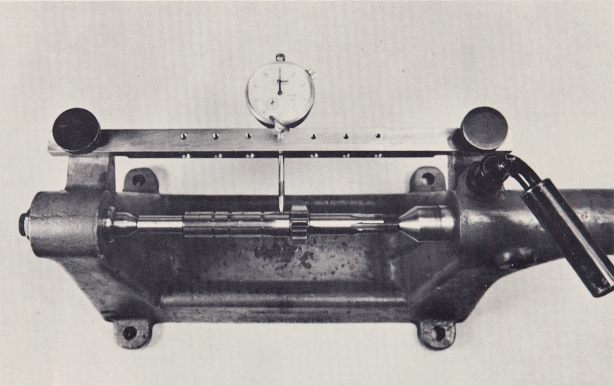

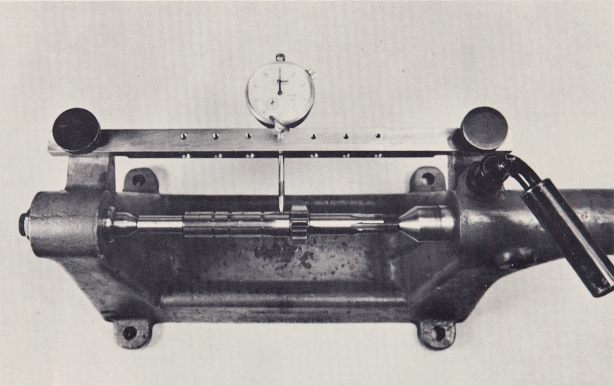

FIG. 38

Page 27

1 . Thoroughly clean each gearbox component and, if available, blow them dry with compressed air. Carefully inspect each part for wear or damage. Any part that has a thrust or friction surface showing a blue color should* be replaced. This indicates that part has been subjected to excessive heat.Section 3:

Checking The Gearbox Components For Wear

2. Carefully check the teeth on all the gears for excessive wear or damage. If you find such damage on one gear, be particularly careful about inspecting its opposing gear on the other shaft, as it may be damaged also.

3. The engaging dogs on all the gears and the condition of the 4th and

5th gear sliding dog should be inspected. If any of these dogs have excessively

rounded edges, they should be

replaced. This could cause two engaging gears to "reject" each other,

or miss a shift. Also, be sure that the sliding gears and engaging dog

are free to slide back and forth on their shafts.

4. If the transmission is being repaired because of broken gear teeth

or a foreign object in the gearbox, or some other breakage resulted in

sudden stoppage of the gearbox and drive train, the mainshaft and layshaft

should be checked for straightness. They may have been bent due to high

loading forces created when such things occur. Place the shaft being checked

in a set of machinist's centers fitted with one dial indicator, as shown

in Fig. 38. Position the indicator on the middle of the shaft and then

rotate it slowly. If the indicator shows a runout of over .001-, replace

the shaft. Also, when breakages of this type occur, check the condition

of the transmission bearings and bushings.

FIG. 38

Page 27