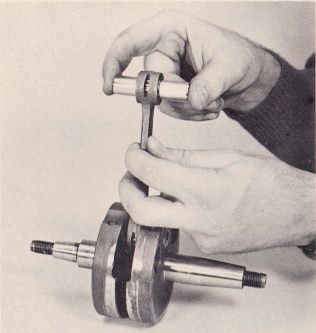

FIG. 22

4. If the amount of clearance in the connecting rod big end bearing has become excessive, it will need replacement. If you can detect a roughness in the bearing, or any perceptible up and down play in the connecting rod, it should be replaced. When replacing the big end bearing, it should be done as an assembly, that is, a new connecting rod, crankpin, rollers and roller cage. This is necessary because the rod is the outer bearing race, and the crankpin is the inner bearing race. To replace one of these without replacing them all is a waste of time and money, as the life expectancy of such a bearing assembly would be extremely short.

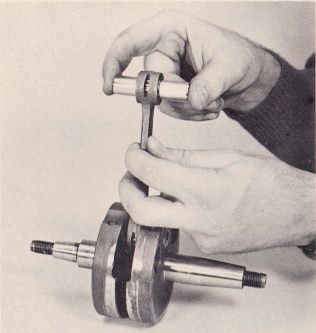

5. The wristpin bearing should also be checked for damage or wear. Clean the inside of the small end of the connecting rod, the wristpin and the wristpin bearing. Put the bearing into the small end of the connecting rod, then insert the wristpin. Position the wristpin so that the area of the pin that the needle bearings ride on is centered in the bearing. Hold the rod firmly with one hand, and try moving the wristpin in all directions to check for clearance (Fig. 22). If you can detect any noticeable play in this assembly, replace the wristpin and bearing and check it again. If no noticeable play is then evident, the old connecting rod assembly can be retained, using a new wristpin and bearing.

FIG. 22

NOTE: Unlike the crankpin bearing assembly, the wristpin need not be

replaced as a complete assembly. This is due to the fact that the crankpin

bearing is subjected to heavy loads and direction changes while turning

at a high RPM. The wristpin bearing is subjected to heavy loads and direction

changes, but instead of rotating 3600 on every revolution of the engine,

it merely oscillates back and forth in an arc of less than 300. For this

reason, individual components of the wristpin bearing can be installed

to obtain the proper clearance, provided the components being reused are

in good shape.

Page 14