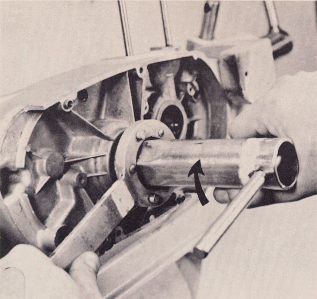

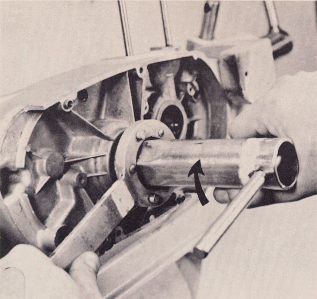

FIG. 18

FIG. 18

6. Remove the nut, washer and sprocket. Tap the end of the 5th driven gear with a soft faced mallet until it is free of the bearing. Finally, remove the sprocket distance spacer from the inside of the transmission oil seal.

7. If you wish to remove the small oil seal from the center of the 5th

driven gear, pry it loose with one of the clutch push rods.

Section 6:

Removing The Crankshaft and Bearings

1. All of the bearings and bushings in the OSSA engine are to be

removed and installed by heating the engine cases. This allows the bearings

to be gently pushed from their mounts and new ones reinstalled without

any force whatsoever being applied to them.

NOTE: Do not drive or press the bearings in or out. This can only result in damage to the bearings and perhaps destruction of the engine cases. If any of the bearings or bushings cannot

2. Heat the primary side engine case with an oven or a small electric stove for about 10 minutes, or until the case temperature reaches approximately 2500 - 3000F. If a stove is not available, you may heat the cases with a torch. If you do so, it is important to keep the torch moving to avoid concentrating the flame on one area, and to heat the whole case evenly. Do not over heat the cases, as they may distort after reaching a certain temperature. Even if you wish to remove only the crankshaft bearings, heat the entire case to prevent its warpage.

3. If you wish to reuse the crankshaft seals, be careful not to allow the flame of the torch to come in direct contact with them or they will be damaged due to excessive heat.

NOTE: It is not recommended that crankshaft seals be reused. They are inexpensive and should be renewed every time the crankshaft is removed or the crankcases parted.

4. When the left hand engine case has been heated to the desired temperature,

wrap a cloth around the magneto side drive shaft and pull the crankshaft

assembly out of the case. The primary side main bearing will remain on

the crankshaft. If the crankshaft will not pull out, support the case on

a small wooden box so that the crank is hanging freely, and push it out

of the case (Fig. 19). If necessary, tap the end of the primary side drive

shaft gently with a rawhide or plastic mallet to remove it.

Page 11